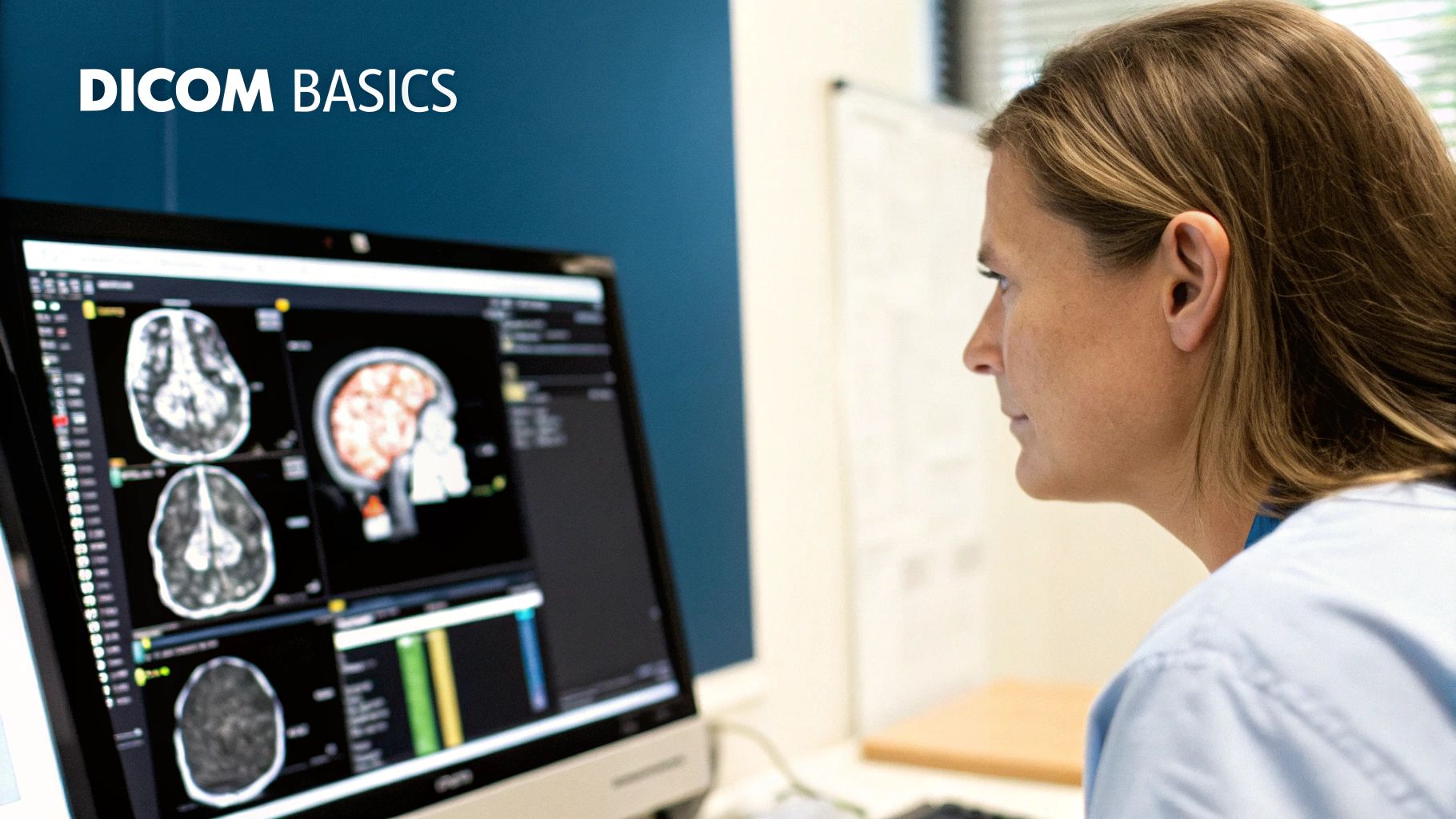

Demystifying DICOM to STL: The Foundation of Medical 3D

The journey from a 2D medical scan to a tangible 3D model begins with a crucial conversion: DICOM to STL. DICOM (Digital Imaging and Communications in Medicine) is the standard format for medical images like CT and MRI scans. These images, composed of a series of grayscale pixels, contain a wealth of anatomical information.

However, to fully utilize this information for 3D printing and visualization, the data needs to be translated into a language that 3D printers understand: STL (Standard Tessellation Language).

Bridging the Gap: 2D Images to 3D Models

This DICOM to STL conversion process bridges the gap between diagnostic imaging and tangible, manipulable 3D representations. Think of it like converting a blueprint into a physical building. The blueprint (DICOM) holds the necessary information, but the construction process (conversion) brings the building (STL) to life.

This conversion creates a 3D mesh, a network of interconnected triangles that define the surface of the anatomical structure. This mesh is what allows 3D printers to build the physical model layer by layer.

This process is increasingly important for medical 3D printing, enabling the creation of highly accurate anatomical models. A study comparing different DICOM to STL conversion software found no statistically significant differences in the shape errors of the resulting STL models, even with variations in file size and polygon count. You can find more detailed statistics here: https://pmc.ncbi.nlm.nih.gov/articles/PMC7393875/

This highlights the precision of current conversion tools.

The Power of Precision: Applications Across Specialties

The level of detail captured in the STL model is critical for various medical specialties. For a neurosurgeon planning a complex brain surgery, the precise contours of a tumor are paramount.

For a cardiologist assessing a heart valve defect, the intricacies of the valve’s structure are essential. DICOM to STL conversion allows medical professionals to visualize, analyze, and manipulate these anatomical structures with incredible detail.

democratiz3D, a free online service, can generate high-quality STL models with up to 2.5 million polygons in under 20 minutes. This speed and precision are especially valuable in fields like oral and maxillofacial surgery.

This translates to improved surgical planning, personalized patient care, and ultimately, better patient outcomes. This conversion isn't just about creating a physical object. It's about unlocking a new dimension of understanding and interaction with the human body.

The ability to hold a patient’s heart, to rotate it, examine it from all angles, and plan a surgical approach with exceptional precision—this is the power of DICOM to STL. This leads us to how we choose the right software tools for this powerful conversion, the topic of our next section.

The DICOM to STL Software Landscape: Choosing Your Tools

Selecting the right software for DICOM to STL conversion is paramount for creating accurate and usable 3D models. The market offers a wide variety of options, ranging from premium software packages to robust free alternatives. This range of choices can be overwhelming. However, by understanding the core features and how they apply to various medical applications, the decision-making process becomes much clearer.

Essential Features for Effective Conversion

Several key features distinguish effective DICOM to STL software. Segmentation, the ability to isolate specific anatomical structures from surrounding tissues, is crucial for creating focused models. Automated segmentation tools can significantly speed up this process, especially for complex structures. This means less manual input is required to accurately represent complex anatomical regions, saving valuable time and resources.

Another important feature is the software's user interface. An intuitive interface simplifies the learning process. This empowers medical professionals, regardless of their technical skills, to use the software effectively. Robust mesh processing tools are also essential. These tools allow for refining the generated STL model, including smoothing surfaces, reducing polygon count, and repairing defects. This level of control ensures the model is optimized for 3D printing and visualization.

In recent years, 3D printing in medicine has become increasingly prevalent, with DICOM to STL conversion playing a central role. As of 2024, tools and libraries are simplifying this process for both professionals and beginners. For example, 3D Slicer is an open-source platform providing extensive tools for image analysis and visualization, including DICOM to STL conversion. Platforms like 3D Slicer have been instrumental in reducing the complexity and cost associated with medical 3D printing, making it more accessible worldwide. democratiz3D further enhances accessibility by offering a free service that converts DICOM files to STL within minutes. For a more in-depth look at this topic, explore this guide: Converting DICOM to STL: A Comprehensive Guide to Methods and Libraries

Balancing Cost and Functionality

Premium software solutions often offer advanced features, such as automated segmentation, sophisticated mesh processing tools, and integration with other medical imaging software. However, the cost can be a barrier for some institutions and individual practitioners. Fortunately, powerful free and open-source alternatives provide comparable functionality, democratizing access to this important technology.

Choosing the right software involves carefully balancing cost against the required features for your specific applications. A research institution focused on complex cardiovascular modeling might prioritize advanced segmentation and mesh processing tools, justifying the investment in premium software. On the other hand, a smaller clinic primarily using 3D printing for surgical planning might find that a free, user-friendly alternative sufficiently meets their needs.

To help illustrate the differences, the following table compares several popular options:

DICOM to STL Conversion Software Comparison

| Software Name | Type | Price | Learning Curve | Key Features | Best For |

|---|---|---|---|---|---|

| 3D Slicer | Open-Source | Free | Moderate | Segmentation, Mesh Processing, Visualization | Research, Education |

| democratiz3D | Online Service | Free | Easy | Fast Conversion, Basic Features | Quick Prototyping, Simple Cases |

| Materialise Mimics | Commercial | Paid | Steep | Advanced Segmentation, CAD Integration | Complex Cases, Medical Device Design |

| Simpleware ScanIP | Commercial | Paid | Moderate | Image Processing, FEA Integration | Biomechanics, Simulation |

This table provides a quick overview of various software choices, highlighting their key features and suitability for different applications. It’s important to research each option further to determine the best fit for your individual needs.

Choosing the Right Tool for the Job

The optimal software choice also depends on the specific medical specialty and the desired outcome. Orthopedic surgeons planning complex bone reconstructions require highly accurate models with detailed surface information. Cardiologists studying blood flow dynamics need models that precisely represent the intricate geometry of the vascular system. Understanding the nuances of each software option and how its features translate into practical advantages is essential for making an informed decision. Ultimately, the software chosen directly influences model accuracy, production time, and, most importantly, patient outcomes.

Mastering DICOM to STL Conversion: A Practical Workflow

This section outlines a practical workflow for converting DICOM data to STL files, guiding you through each key step. The process begins with obtaining high-quality DICOM data, the very foundation upon which accurate 3D models are built. Compromised input data inevitably leads to a compromised 3D model.

Preprocessing: Preparing Your DICOM Data

The first step is preprocessing the DICOM data. This crucial stage may involve noise reduction, contrast enhancement, and image resampling. Much like preparing wood for carving, you wouldn't begin with a rough, uneven piece. Preprocessing ensures a clean, consistent dataset ready for conversion. These techniques significantly improve the final 3D model's accuracy.

Segmentation: Isolating the Target Anatomy

Next is segmentation, isolating the specific anatomical structures needed for the 3D model. This creates a focused, manageable STL file. If creating a model of a bone fracture, for example, you'd segment the bone from the surrounding soft tissues. This can be done manually or with automated tools, depending on the anatomical complexity and the software used.

Conversion: Generating the STL Model

With the segmented data prepared, we move to the core process: DICOM to STL conversion. Various software options exist, each with its own strengths and weaknesses. The best choice depends on factors like anatomical complexity, required detail, and budget. Some packages utilize algorithms like marching cubes to create the 3D mesh.

Post-Processing: Refining the 3D Model

Post-processing is essential after conversion to refine the STL model. This might involve smoothing surfaces, reducing the polygon count, or repairing any mesh defects. This step is similar to sanding and polishing a wood carving, refining its appearance and functionality. Post-processing ensures a print-ready model suitable for its intended purpose.

Validation: Ensuring Anatomical Accuracy

Finally, validation is critical. This ensures the 3D printed model's anatomical accuracy. It often involves comparing the model to the original DICOM data or using other quality assessment methods. Validation confirms that the model accurately represents the patient’s anatomy and is suitable for its application, whether for surgical planning, medical education, or patient communication.

Addressing Common Challenges in DICOM to STL Conversion

DICOM to STL conversion has its challenges. Accurately segmenting low-contrast tissues can be difficult. Preserving small vessels during segmentation also presents complexities. Imaging artifacts in the original DICOM data can further compromise the STL model's quality. However, careful preprocessing, proper segmentation techniques, and meticulous post-processing can overcome these hurdles.

Example Workflow for a Skull Model from CT Scan Data

Consider creating a skull model from CT scan data.

- Preprocessing: Reduce noise and enhance bone contrast in the CT images.

- Segmentation: Isolate the skull from the surrounding soft tissues and air.

- Conversion: Use software like 3D Slicer to generate the STL model.

- Post-Processing: Smooth the skull's surface and reduce the polygon count for efficient 3D printing.

- Validation: Compare the STL model to the original CT data to ensure accuracy.

This practical workflow, with its emphasis on quality control, delivers a reliable and clinically useful product. Understanding and implementing these steps establishes a solid foundation for successful DICOM to STL conversions.

Beyond The Obvious: Innovative DICOM To STL Applications

While DICOM to STL conversion is widely used in surgical planning, its applications extend far beyond the operating room. From patient education to medical research, DICOM to STL models are reshaping healthcare.

Transforming Patient Education and Communication

One significant application lies in patient education. Understanding complex medical conditions from 2D images can be challenging. However, a 3D model of their own anatomy provides patients with a tangible representation, improving comprehension and reducing anxiety. For instance, a patient undergoing heart surgery can better visualize the procedure with a 3D printed model of their heart.

Revolutionizing Medical Education And Training

DICOM to STL conversion is also transforming medical education. Students can interact with realistic anatomical models, enabling them to explore complex structures in three dimensions. This hands-on approach provides a deeper understanding than traditional methods. The result is more effective learning and better-trained healthcare professionals. Many medical schools and training programs are integrating these models into their curricula.

Enabling Personalized Implant Design

This technology is also crucial for personalized medicine, particularly in designing custom implants. DICOM data from a patient's CT or MRI scan can be used to create a precise 3D model of the implant area. This model then becomes the blueprint for designing and manufacturing a perfectly fitting implant, improving functionality and reducing complication risks.

Advancing Medical Research And Visualization

DICOM to STL conversion is also propelling medical research. Researchers use these 3D models to visualize disease progression, study anatomical variations, and develop new treatments. For example, neurosurgeons can use 3D printed models for improved precision during complex brain tumor surgeries. Pediatric specialists can also plan interventions for congenital heart defects with increased confidence.

Integrating STL Data Within DICOM

The use of DICOM to STL conversion is expanding beyond traditional medical imaging. In digital dentistry, STL format 3D scanning data is increasingly important for designing dental restorations and surgical guides. Efforts are underway to integrate STL data within the DICOM format to enhance patient data integration and confidentiality. As of 2020, over 140 file formats were used for 3D graphic representation. This highlights the need for standardized formats like DICOM to manage and secure patient data. Learn more about 3D graphic format standardization. This integration is essential for comprehensive treatment planning and efficient record management.

Quantifiable Benefits of DICOM To STL

The advantages of these applications are measurable. Studies show that using 3D models in surgical planning reduces surgical time, improves patient outcomes, and minimizes complications. Similarly, using 3D models in patient education leads to better patient understanding and increased satisfaction with care.

These examples showcase the broad impact of DICOM to STL conversion. It is not just a technical process but a driver of advancements across healthcare. From empowering patients to enabling life-saving procedures, DICOM to STL models are changing how we interact with the human body and transforming medical care.

From Good to Outstanding: DICOM to STL Quality Mastery

Creating anatomically accurate 3D models from medical imaging data is a complex process. It's not simply a conversion from one file format to another. It requires a deep understanding of both DICOM and STL formats, along with the specialized techniques that transform a good 3D model into an outstanding one.

Balancing Polygon Count and Anatomical Precision

A critical factor in STL model quality is the polygon count. This refers to the number of triangles used to create the 3D mesh. A higher polygon count typically results in a more detailed model. However, it also increases file size and processing time. The challenge lies in finding the right balance between anatomical accuracy and a manageable file size. For example, a highly detailed model of the inner ear may need a much higher polygon count than a model of the femur.

This balance is also essential for compatibility with various 3D printing technologies. Some printers handle high-polygon models easily, while others struggle with complex meshes. Optimizing the polygon count for the intended 3D printing technology is key.

Preserving Critical Structural Relationships

While detail is important, maintaining the relationships between anatomical structures is paramount. A 3D model of the heart, for instance, must accurately represent the shape of the ventricles and their connection to the atria and major vessels. Losing these relationships during the DICOM to STL conversion can make the model clinically unusable.

This requires meticulous attention during the segmentation process. Skilled medical modeling professionals use specialized software and techniques, such as 3D Slicer, to ensure these crucial structural connections are preserved throughout the conversion process.

Optimizing for Specific 3D Printing Technologies

Different 3D printing technologies have unique requirements for STL models. Fused Deposition Modeling (FDM) printers often work best with watertight meshes and require careful consideration of wall thickness. Stereolithography (SLA) printers are typically more tolerant of intricate details but can be sensitive to the model’s orientation during printing.

Therefore, tailoring the STL model’s characteristics to the specific 3D printing method is vital for a successful print.

Specialized Approaches for Challenging Anatomies

Certain anatomical structures, like thin-walled blood vessels, pose unique challenges for DICOM to STL conversion. These delicate structures require careful segmentation to avoid losing crucial details. Complex vascular networks demand specialized algorithms to accurately depict their intricate branching patterns. Dynamic tissue interfaces, such as those in joints, require advanced techniques to capture the dynamic interplay of different tissue types. In these cases, sophisticated software and experienced professionals are essential for producing high-quality STL models.

Quality Assessment and Iterative Improvement

A rigorous quality assessment is critical for validating STL models. This usually involves visual inspection, comparing the 3D model to the original DICOM data, and utilizing software tools like Meshmixer to analyze the mesh for defects. Iterative improvement, involving refining the segmentation, conversion, and post-processing steps, is often necessary to achieve the desired level of quality.

Real-world case studies show how these quality differences directly affect clinical utility. A surgeon using a precisely segmented and optimized 3D printed heart model can plan a complex procedure with greater confidence and precision. Conversely, a model with inaccuracies or missing details could lead to misinterpretations and potentially negative surgical outcomes. The quality of the DICOM to STL conversion is thus directly linked to the 3D printed model’s effectiveness in improving patient care.

The Democratization of DICOM to STL Technology

The conversion of DICOM (Digital Imaging and Communications in Medicine) data to STL (Standard Tessellation Language) files was once a highly specialized process, limited to labs equipped with expensive software and staffed by experts. However, recent developments are making this technology significantly more accessible to a broader range of clinicians and researchers. This democratization is fueled by several key factors, including cloud computing, AI-assisted segmentation, and user-friendly interfaces.

Cloud Computing: Breaking Down Barriers

Cloud-based DICOM to STL conversion services remove the need for costly software installations and powerful local hardware. This significantly lowers the financial barrier to entry, enabling smaller clinics and individual practitioners to utilize this technology. Cloud platforms also offer scalability and flexibility, allowing users to process large datasets and access their work remotely with an internet connection. This increased accessibility encourages collaboration and knowledge sharing, especially valuable for healthcare providers in underserved areas.

Cloud-based access promotes collaboration and provides opportunities for medical professionals to share knowledge and expertise worldwide.

AI-Assisted Segmentation: Simplifying Complex Tasks

Segmenting, or isolating specific anatomical structures from surrounding tissue, is one of the most time-consuming and technically challenging steps in DICOM to STL conversion. AI-powered segmentation tools automate this complex process, dramatically reducing the time and specialized expertise required. These algorithms can precisely identify and isolate complex structures like bones, organs, and even delicate blood vessels with minimal manual input. This streamlined workflow empowers clinicians without extensive medical image processing training to create high-quality STL models. This efficiency allows medical professionals to focus more on patient care and less on technical image manipulation.

Intuitive Interfaces: Empowering Users

Modern DICOM to STL software is designed with user-friendliness in mind. Intuitive interfaces simplify the conversion process, guiding users through each step with clear instructions and visual feedback. This streamlined approach reduces the learning curve, enabling medical professionals with diverse technical skills to effectively utilize the technology. This ease of use encourages wider adoption, empowering clinicians to directly integrate 3D models into their practice, enhancing surgical planning, patient education, and overall patient care. Clear visual feedback and simplified workflows enhance usability and encourage broader adoption by healthcare providers.

To illustrate the evolution of this technology, consider the following table:

Introduction: The following table summarizes how DICOM to STL conversion has become progressively more accessible over time.

| Era | Required Expertise | Cost Barrier | Processing Time | Accessibility Level | Key Technologies |

|---|---|---|---|---|---|

| Early Stages (Pre-2010s) | High | High | Long | Very Limited | Specialized software, local hardware |

| Transition Phase (2010s) | Medium | Medium | Moderate | Limited | Cloud computing, early AI tools |

| Current Era (2020s+) | Low | Low | Short | High | Advanced cloud platforms, refined AI algorithms, intuitive interfaces |

Conclusion: As the table demonstrates, DICOM to STL conversion has evolved from a complex and expensive process to one that is significantly more accessible and user-friendly, thanks to advancements in technology and software design.

Services like democratiz3D offered by Embodi3D, enable users to convert DICOM files to STL models without extensive expertise. Open-source software such as 3D Slicer offers a platform for advanced image processing and segmentation, further supporting the creation of high-quality STL models. This combination of accessibility and powerful features is driving innovation in medical 3D printing globally. You can learn more about this evolution at Embodi3D.

The Future of Accessible Healthcare

These advancements are reshaping healthcare delivery, especially in underserved areas with limited access to specialized medical resources. Cloud-based services, AI-powered tools, and user-friendly interfaces are empowering clinicians worldwide to utilize 3D printing, improving surgical outcomes, enhancing patient education, and driving medical innovation. Continued development of these technologies promises to further democratize access to advanced medical tools, ultimately contributing to better healthcare for all. Improved access to these technologies promises better healthcare outcomes for patients around the globe.